Instrumented Impact Testing

The Rosand IFW 413 Instrumented Impact Tester

Impact testing today constitutes an important end product and fit for purpose test.

Following manufacture many products will experience some form of service impact specific to their environment, it is the aim of the impact tester to replicate these service impacts in order to assess their fitness for purpose.

Impact testing is generally governed by standards which cater for a wide range of materials including:

- Polymers

- Polymer Composites

- Metals

- Ceramics

Instrumented impact test

Listed below are some of the more common standards:

Testing to the following Plaque and Film standards

A specialised Film Anvil and a Charpy Striker/Mass Assembly

- ISO 6603 - Determination of Multi-axial Impact Behaviour by the Instrumented Puncture Test (plaque thickness-1 to 4mm). Geometry: 40mm anvil and clamp, 20mm hemispherical striker

- BSI 2782 part 3 method 352D - Determination of Falling Weight Impact Resistance of thin Flexible Sheet. Geometry: 127mm diameter anvil/clamp, 38mm hemispherical striker

- ISO 179-2:1999 - Plastics, determination of Charpy Impact strength

- ASTM D3763 - Standard Test Method for High Speed Puncture Properties of Plastics using Load and Displacement Sensors. Geometry: 3" diameter anvil/clamp; ½" hemispherical striker Geometry: Charpy & Izod

- DIN 53373 - Testing of Plastic Films Impact Penetration Test with Electronic Data Recording Geometry: 40mm diameter anvil/clamp, 20mm hemispherical striker

- ISO 7765 - Determination of Impact Resistance by the Free-Falling Dart Method (film/plaque thickness up to 1mm) Geometry: 40mm anvil and clamp, 20mm hemispherical striker

- General sub-assembly impact testing - geometry subject to sub-assembly dimension, may require specific jig and/or fixture. Barely Visible Impact Damage (BVID); low energy, non-penetrative test aiming to replicate de-lamination in composite materials Facility

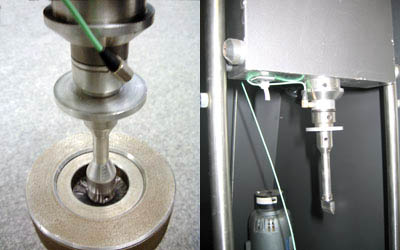

Rosand IFW413 Instrumented Falling Weight Impact Tester

- Tower Height: 1.3m

- Maximum available impact velocity: 5m/s

- Energy Range: 0.05 to 200J

- Force range: 10 to 50,000N

- Data acquisition: 12bit resolution, 670ksamples/s, 4000 data points

- Temperature controlled environment

Telephone:

01299 251 914

Our postal address:

Fleming

Polymer Testing Ltd,

Holly House

Hartlebury

Kidderminster

DY11 7TE UK